How to best convert light into production

Systematic cultivation produces the best possible fruiting vegetable production and quality. Crop consultant Wim van Wingerden highlights how the use of a light plan can increase production.

The production of fruiting vegetables comes down to as effectively as possible converting available solar energy (Joules) into kilos of fruit. In actual practice insight into how many Joules are needed for each gram of fruit has grown. For example, between 10 and 11 J/g is required for sweet peppers. But managing this is not as easy as it sounds. Everything a grower does affects the result. Heating, ventilation, coating and shading. The interaction of these factors must be optimal. A methodical system (crop plan) most certainly can be helpful.

Sweet Peppers

Wim van Wingerden advises horticultural companies throughout the world. Based on his experience he has developed a practical system, named ProJoules. He explains this system using sweet peppers as example. “From actual practice we know that sweet peppers can use a maximum of 1,700 Joules per day. However, during a major part of the year there is less radiation and in another part there is too much,” he explains. The radiation pattern over the course of the year differs by country and by region. On the basis of the expected radiation during the year and the optimal/maximum radiation your crop is able to withstand, you decide when to apply a coating or to deploy the shading canvas. Because the light is below the optimum during a significant part of the year, you will want to get more light into the greenhouse during that period by increasing the glass’ transmission capacity, for example by applying AntiCondens and AntiReflect.

Plant Load

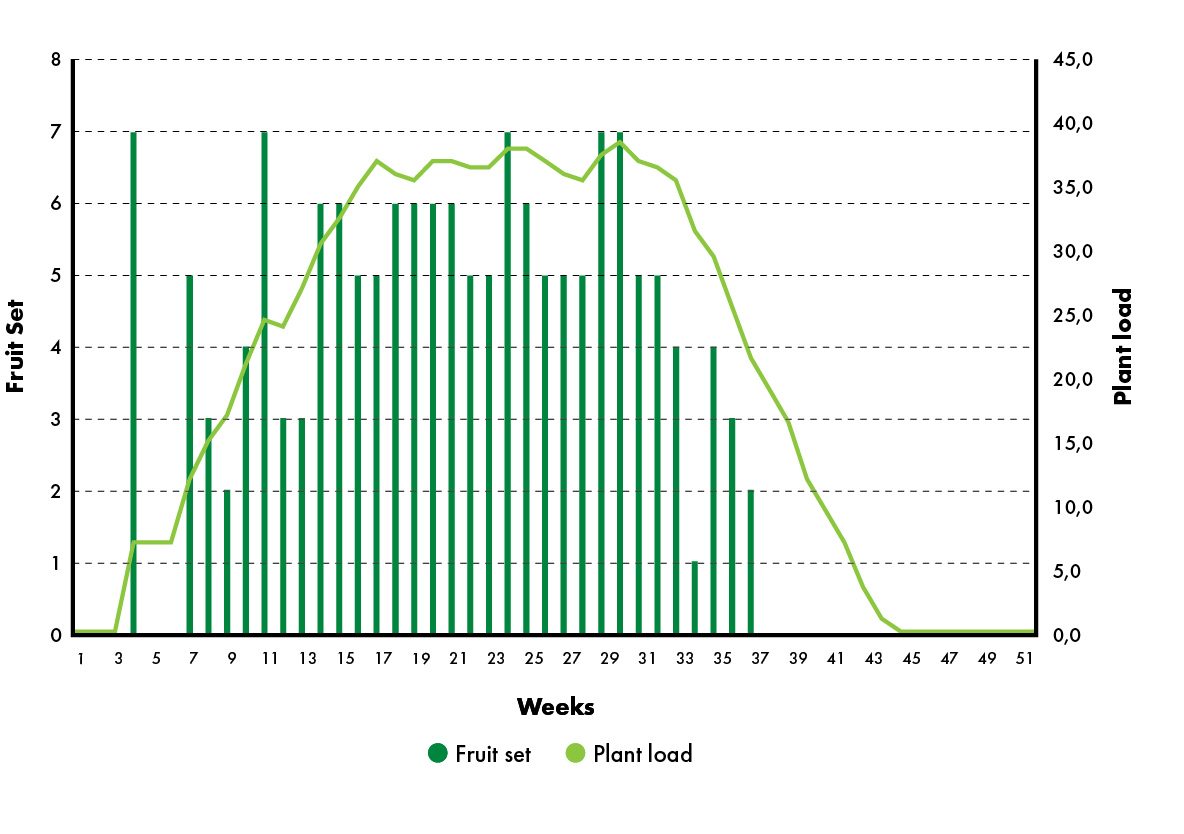

Next, it is important to as effectively as possible exploit the available Joules throughout the entire year. “At the start of the season, you can develop a light plan based on the long-term average. After this you record the fruit setting and light intensity and you enter the desired fruit weight per week. The system then indicates the number of Joules of radiation that is required in the subsequent weeks.” You can use this information to determine the size of the fruit setting in these weeks. When little light is expected to be available you may have to remove fruit (pruning). When more light is available, you can retain more fruit,” he says. The trick is to find the right balance between the required and available Joules.

The light green line in the graph indicates how well you are managing to exploit the available Joules. In actual practice, beautiful and poor weeks will alternate; this means it is impossible to ever reach the ideal curve. On the other hand, it is possible to approach that curve. “If – in a moderate climate – you already have an ample fruit setting in week 4, for example, the model may indicate that no additional fruit may set in the following two weeks. It may then be necessary to prune some fruit and/or you may have to adjust your heating regime. This way you avoid having to make emotional decisions based on a few beautiful days,” says Van Wingerden.

Temperature-controlled growth

Temperature-controlled growth

As a control measure you must keep an eye on the top of the plant. “You must prevent the stem from becoming too thick, because this means that the plant is storing too many sugars in its vegetative growth (stems and leaves). As soon as you see an increase in the diameter, you should increase the temperature in the greenhouse,” he says. In addition, the Joule-demand referred to earlier also plays an important part. The grower’s green thumb, assisted by crop advisors, continues to form the basis. However, by systematically recording the climate and crop data you can base your advisory consultations on actual data instead of estimates. “It is a decision support system. After a season you can review the progress at various stages and evaluate when things could have been done better. You can then apply the insights gained in the next season. Furthermore, you will be giving more thought to light efficiency. The key is to keep the plant in balance throughout the entire season. That will yield the maximum number of kilos and the best quality,” says Van Wingerden.